In our brand new industry spotlight, we speak with guitar designer, Ed Taylor of Ed Taylor Designs. This 18-year-old from Osmotherley, North Yorkshire is a first-year student at York St John University who has a clear passion for playing music himself, and crafting bespoke work so that others can “rock-out” with a model that looks, and feels exactly the way that they want. His custom designs are slick, easy to manage and they look frickin’ awesome. We chat to Ed about his inspirations, and ideas for the future.

“I have found a gap in the market”

S] Hi Ed, can you introduce yourself and tell us about your background?

ET] I am doing Product Design at York St John University and I am in my first year. It’s going really well and I am enjoying it a lot. I won the Engineering Inspiration Award from Venturefest a few months ago as a result of my guitar design work and that got me on to the course.

S] What is it like winning awards at such a young age?

ET] It’s really great. It was a big surprise when I won the Engineering Inspiration Award. I was really pleased. It was an amazing feeling!

S] How do you think the skills that you are gaining as part of your degree will support you as you establish yourself?

ET] The lecturers at YSJ are very good, and they have a lot of experience and that is what I don’t have at the moment. There is so much that I am working on, and I have received a lot of help and support. There is still a lot that I don’t know! It’s very business-orientated as well, so that will help me develop that side of what I am going to be doing.

S] So, what sparked your interest in creating guitars?

ET] Well, I had always really wanted to make a guitar from the period where I was doing my AS Levels. My teacher told me that it would be too difficult. For the first year, I made a chair and that was not really good enough for me. In my second year, I really forced it. When I finished my AS-Levels, during the summer holidays and over the six-week period I was constantly designing my first guitar and then when I came back to do my A-Level [in Product Design And Resistant Materials], I had all of this work to show my tutor and he allowed me to go ahead with it. I really enjoyed that design process.

S] How do you think you have developed as a designer since that point?

ET] I think that I am constantly developing, and as a designer, you have to figure out what works and what doesn’t. I made my first guitar and that was fantastic, but there are so many improvements that I could make now!

S] What are your future aims and goals?

ET] After my degree, I hope to have a ‘top-notch’ guitar company set-up. The products will be very ‘high-end’ and aimed at the more ‘experienced’ guitar player. The guitars will be geared towards the metal and hard rock genre, at least at the start and I plan to diversify later into other styles. I want to have that set up before I finish university in two years. I’ve got a few models that I have nearly finished now, and I am going to try and have a full marketing campaign set-up for them by September of next year.

S] How is that marketing going to take place?

ET] Because the guitars are all ‘high-end’, I am aiming to have them all sold through my website. That’s how the business will work. I won’t have them in guitar shops – it will be very direct, and each model will be made to order. I’ve had a lot of help from different people within various organisations. I’m not going to have time to manufacture the guitars at the moment, because of my university commitments and money. One thing that I really want to do, is make sure that all of the guitars are manufactured in the UK. After speaking to various makers in this country, they say, ‘If you want to make it work, then you have to go to South Korea’, but then I don’t want to do that. I don’t believe in outsourcing production abroad, because I don’t think that it is very ethical. Some of the bigger brands out there at the moment really do exploit the workers that they have and the conditions that they work in are pretty terrible. That’s just started to come to people’s attention.

S] Do you play in a band yourself?

ET] I have been playing guitar for about seven years, and I have had a few bands in that time. At the moment, I don’t have a band set-up, and I am trying to find a singer and a bassist to work with. I’ve got loads of songs – actually, there’s more than enough there for a double-album! We’re going to start doing some gigs once that’s sorted. We are going to be doing metal music – when I am writing, I try to make the songs sound a bit different instead of just the generic open-D chord, and chugging away!

S] Who are your biggest musical influences – what kind of stuff do you listen to when you are creating?

ET] Everything really. I am a massive metal fan, though. Some of my favourite bands include Trivium, Metallica and Children Of Bodom. I listen to ‘older’ stuff too, including Led Zepplin, Wishbone Ash and Cream. Really good stuff.

S] So, how does the guitar design business work at the moment?

ET] Well, I am in talks with a manufacturer in the UK at the moment who can build the guitars for me. I am getting a quote from them soon. It’s not ideal for me to have someone else making them for me, but right now it’s better while I concentrate on studying. Hopefully, later on I will be able to get my own little factory to work in!

S] You’ve had a lot of attention recently in terms of exhibitions, and you’ve been asked to speak at Venturefest next year in York – do you feel that you can promote and sell your guitars effectively yet?

ET] It’s great that I have been given all of those opportunities. It’s making me develop my skills because I haven’t had that much experience in terms of promoting, but being able to have that now is great. In terms of selling, I think I will be able to do it. My dad’s got his own business, so I have learned some skills. I think I have definitely found a gap in the market, creating really good guitars with unique designs and different materials. So many of the manufacturers out there are just copying each other all of the time. I mean, stuff that’s around now – the Stratocaster and Les Paul have been going for ages now – I think that I can do something that’s a little more ‘fresh’.

S] How do you fit everything in?

ET] There is a lot to do, and it is very hard to manage sometimes – getting on with uni work and doing the guitars as well. I enjoy designing guitars and making them so much, and I am constantly doing it. Whenever I have any spare time, that’s what I am doing. I could spend all night designing a guitar and working on it. It’s never a chore. I have a great time doing it.

S] What do you do in your spare time?

ET] I spend it playing guitar! I also play drums as well, but I am no Joey Jordison [Slipknot]!

S] How would you offer advice to someone who wants to follow in your footsteps?

ET] You need a lot of patience. When things are not going well, you have to not get stressed, step back from it and come back later with a ‘cooler’ head on. When I was doing my first guitar, I remember just putting so much effort into it.

S] What makes you different to other makers?

ET] First off, I want everything to be made in Britain and the the UK. It’s bad in the UK, because we don’t have the production any more, but we are more than capable of making great stuff. I don’t think that it’s good for companies to outsource production abroad and to have workers in poor conditions manufacturing equipment. It’s not on. There are a few smaller manufacturers in Britain, and a number of people who are operating like I want to be – the problem is that they are all copying the bigger brands out there like Gibson or PRS. I am trying to get into that gap by creating completely new designs and something different. I want to make good guitars for metal musicians. I am aiming towards the female market as much as possible too in the future by designing guitars to appeal specifically to girl-players.

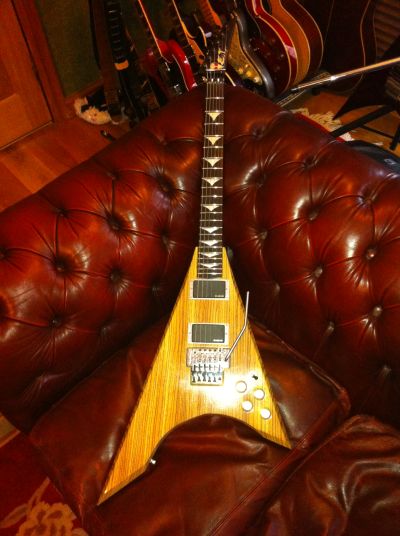

I use as few ‘after-market’ parts as is possible. The only things that are bought in are the pick-ups, the bridge and the machineheads – everything else is manufactured by me including the pick-up rings. I am trying to use the best quality of material that I can. Lots of manufacturers use plastic on a £2,500 guitar and it’s so cheap and terrible. For the cover plates on the back of my guitar [pictured below], I have used alluminium and the pick-up rings have been designed with inspiration from the bezel on a Rolex watch – it has saw-tooth indentations going around it. The volume controls and tone knobs are all mine, they have been made out of aluminium, and for those I took inspiration from a piston-head. Again, there are grooves incorporated there, for when the player’s hands get sweaty from playing live. My logo has a Mother of Pearl inlay set in to it. All of the inlays are custom “shark-tooth” ones, and they are set-in by hand. I use stainless steel frets throughout because they last ten-times longer and are much nicer to play with. The finishing process is extensive – it’s had two covers with coated grain filler, sixteen coats of sanding sealer with four coats of paint on the back and then, another twelve coats of top coat lacquer and then it’s buffed to a high gloss. The fret boards are African ebony, and there’s a nice curve so that a player can sit down with it and rest it over a knee – it can be put in a classical guitar stance or put on its side – it’s a bit easier to play when sat – I’ve thought about the ergonomics a bit! All of the guitars that I make will be set-neck instead of bolt-on. The first one I did is a bolt-on one, but I have changed the design and the rest will be set-neck. Each guitar will be engraved with my logo and its own serial number. I’ve used a water-based finishing material throughout because it’s more environmentally friendly.

S] What’s the process like for you when you are creating a guitar?

ET] I don’t do much drawing. I feel a bit bad on my course actually when I see all of these people doing amazing drawings and presentation drawings because I can’t do it. I am learning! I am a lot more computer-based using Venturefest. To start-off, I will do a quick sketch of some design features and then leave it at that. Then I will start working on the cad stuff, and design that. Then, I develop it from there.

S] Would you consider taking on students for internships?

ET] Yeah, I’d love to do something like that if I got big enough! I’ve already inspired one lad at my old college. He’a making a guitar now, after seeing mine. I’ve been giving him advice. I love to help people. I had some off of a luthier who was really helpful – his name is Nigel Stockbridge. He helped me with all of the technical stuff and that side of creating a guitar. It was great to get that support, and I would love to do the same for someone else.

S] What keeps you going when all of your friends are out and enjoying themselves – do you get enough social time?

ET] I have enough. I’ve got to be able to keep that work and play balance. If it’s something that I am passionate about, then it’s not going to be a chore. It’s not work for me. It’s fun to develop my ideas and I get a lot out of it at the end. A couple of months ago, I set up a limited company called Ed Taylor Design Ltd. I am hoping to do other stuff apart from guitars. Guitars is my main thing, but I enjoy designing other stuff to fund them.

S] What other stuff do you work on?

ET] Anything, really. I have designed these stackable cube mugs [pictured above], and I get orders from restaurants who want to have them in guest rooms and things like that. I want to use the same ideas that I have for creating guitars and put those into working with other objects. The mugs are in the shape of a cube, and you can drink from the corner. The handle’s internal, and it is very different.

S] Where can people go if they want to look at your stuff?

ET] I haven’t got a website, but I am aiming to have one online by summer. If anyone wants to get in touch meanwhile, the they can e-mail me at: ed.taylor@btconnect.com.

S] Can you think of a defining moment of your career thus far?

ET] I think winning the Engineering Inspiration Award from NYBEP, because it really made me believe in myself and made me realise that it would be possible to take this further. I now have a lot of drive and will keep pushing myself.